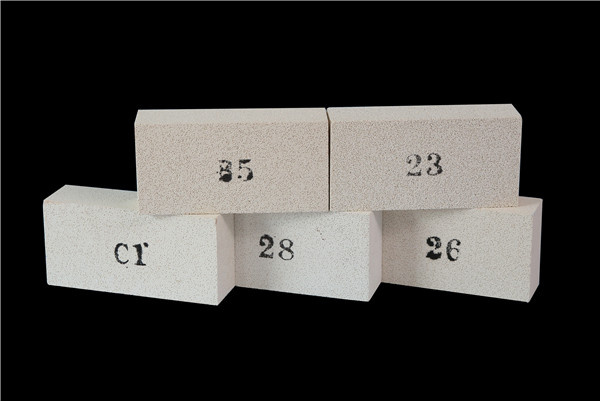

I-Mullite light-weight insulation izitena

Ingcaciso yeMveliso

Izitena zobunzima be-mullite ziqulethe i-porosity ephezulu, enokugcina ubushushu obuninzi kwaye ngoko iyanciphisa iindleko zepetroli.Ngeli xesha ubunzima bokukhanya buthetha umthamo omncinci wokugcina ubushushu, ngoko ke kufuneka ixesha elincinci xa i-onti ifudunyezwa okanye ipholile.Ukusebenza kwamaxesha athile ngokukhawuleza kuyasebenza.

Ingasetyenziswa kwiqondo lobushushu ukusuka kwi-900 ukuya kwi-1600 ℃.

Isetyenziswa ikakhulu njenge-kiln lining kubushushu obuphezulu (ngaphantsi kwe-1700 ℃) iikhilthi zeeseramikhi, i-petrochemical, isinyithi kunye noomatshini.

Iimpawu eziqhelekileyo

I-conductivity ephantsi ye-thermal, umthamo ophantsi wokushisa, umxholo ophantsi wokungcola

Amandla aphezulu, ukuxhathisa ukothuka kwe-thermal, ukumelana nokukhukuliseka

Ubungakanani obuchanekileyo

Usetyenziso oluqhelekileyo

I-Ceramics roller kiln kunye ne-shuttle kiln: isitena esiqhelekileyo, isitena somngxuma we-roller, isitena se-hanger,

Ishishini leMetallurgy: iziko elitshisayo;umgca wangaphakathi weekhilni ezifumanekayo

Ishishini lamandla: ukuvelisa umbane kunye nezixhobo zebhedi ezimanzi

Electrolytic Aluminium ishishini: eziko yangaphakathi

Iimpawu zemveliso eqhelekileyo

| Mullite ukukhanya-ubunzima ukugquma izitena Product Properties | ||||||

| Ikhowudi yeMveliso | I-MYJM-23 | I-MYJM-26 | I-MYJM-28 | I-MYJM-30 | I-MYJM-32 | |

| UHlelo loHlelo (℃) | 1260 | 1400 | 1500 | 1550 | 1600 | |

| Ubuninzi (g/cm³) | 550 | 800 | 900 | 1000 | 1100 | |

| Isigxina somgca thrinkage (℃×8h) | 0.3 (1260) | 0.4 (1400) | 0.6 (1500) | 0.6 (1550) | 0.6 (1600) | |

| amandla acinezelayo (Mpa) | 1.1 | 1.9 | 2.5 | 2.8 | 3 | |

| Amandla Repture(Mpa) | 0.8 | 1.2 | 1.4 | 1.6 | 1.8 | |

| I-Thermal conductivity (W/mk) (350℃) | 0.15 | 0.26 | 0.33 | 0.38 | 0.43 | |

| Ukwakheka kweekhemikhali (%) | Al2O3 | 40 | 54 | 62 | 74 | 80 |

| Fe2O3 | 1.2 | 0.9 | 0.8 | 0.7 | 0.5 | |

| Qaphela: Idatha yovavanyo ebonisiweyo ziziphumo eziqhelekileyo zovavanyo oluqhutywe phantsi kweenkqubo eziqhelekileyo kwaye zixhomekeke ekuhlukeni.Iziphumo akufunekanga zisetyenziselwe iinjongo ezithile.Iimveliso ezidwelisiweyo zihambelana ne-ASTM C892. | ||||||