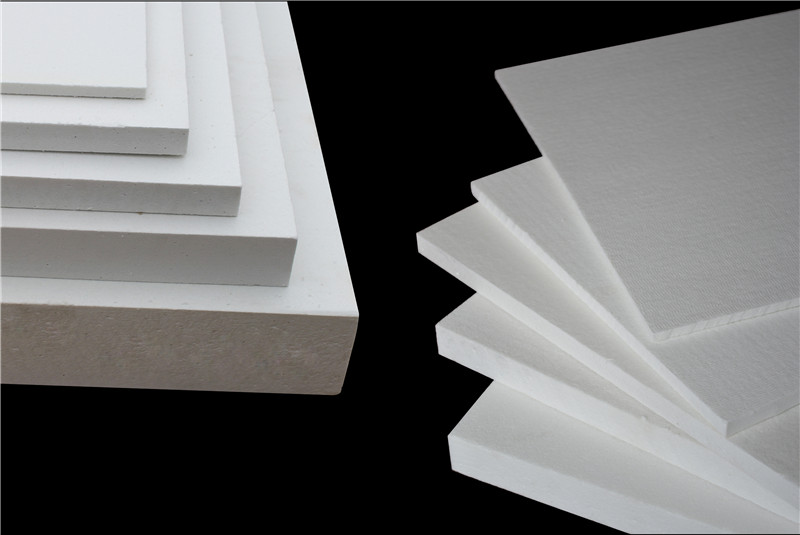

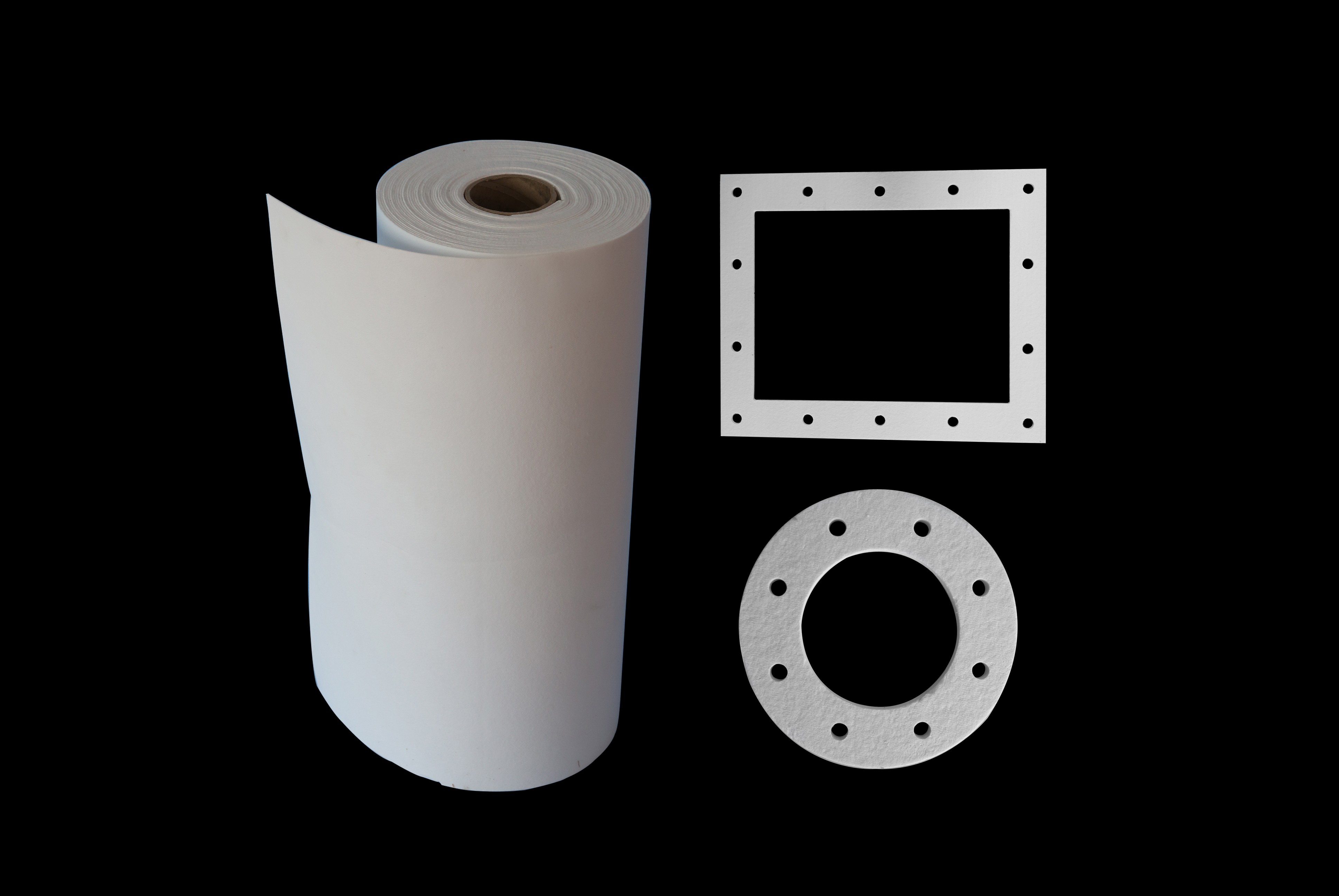

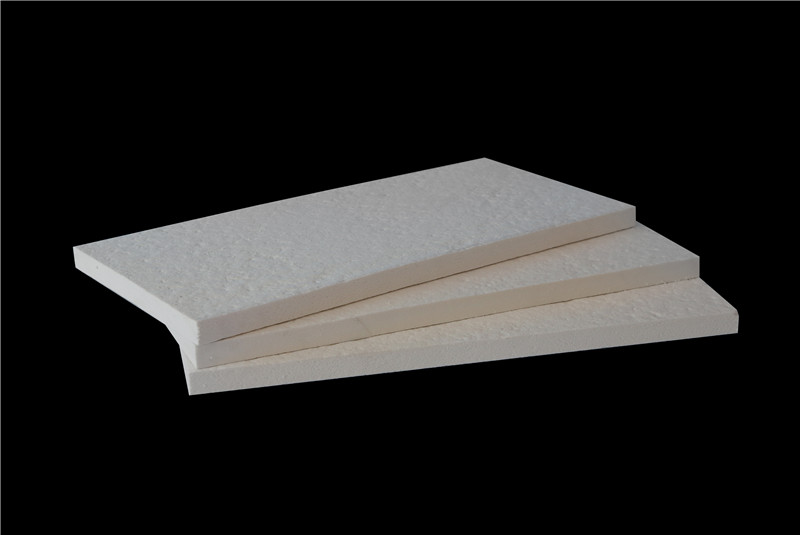

Imveliso ye-Ceramic Fiber Foam / i-RCF Foam

Ingcaciso yeMveliso

Itekhnoloji ye-Ceramic fiber foam iqala isebenzisa itekhnoloji ekhethekileyo yokudibanisa ifayibha ye-ceramic isambuku kunye ne-binder esekwe emanzini, emva koko usebenzise isixhobo esikhethekileyo ukutshiza ugwebu kumphezulu wezixhobo.Emva kokumisa ugwebu luzinzile, lungabinamthungo, lomelele kwaye lutyebe ngokwaneleyo.I-Ceramic fiber foam ayinayo ityhefu, ayinancasa, i-asidi kunye ne-alkali ukumelana, i-antibacterial, ihlala ihlala njalo njalo.

Iimpawu eziqhelekileyo

I-conductivity ephantsi ye-thermal, i-insulation efanelekileyo

Ukwazi ukumelana nomlilo

Ukufunxwa kwesandi okugqwesileyo

Uzinzo olugqwesileyo lweekhemikhali, oluzinzileyo

Usetyenziso oluqhelekileyo

Isakhiwo sentsimbi singatshi

Iziko lokufudumeza i-Petrochemical

Iziko lokufudumeza iMetallurgical

Umbhobho oshushu

Iimpawu zemveliso eqhelekileyo

| IiPropati zeMveliso ye-Foam eqhelekileyo yeMveliso | |||

| Ikhowudi yeMveliso | Igwebu loBunyulu obuMgangatho | I-Alumina Foam ephezulu | Umgangatho weZirconium Foam |

| Iqondo lobushushu iBanga℃ | 1260 | 1350 | 1430 |

| Uxinaniso lweNominal(kg/m³) | 220 ± 15 | 220 ± 15 | 220 ± 15 |

| I-Thermal Conductivity(Mean Temp 500℃)W/(mk) | ≤ 0.153 | ≤ 0.153 | ≤ 0.153 |

| Ucutho olusisigxina lomgca (%) | 1260℃×6h≤3 | 1350℃×6h≤3 | 1430℃×6h≤3 |

| Isiqinisekiso soMgangatho we-ISO | ISO9001-2008, ISO14001-2004 | ||

| Qaphela: Idatha yovavanyo ebonisiweyo ziziphumo eziqhelekileyo zovavanyo oluqhutywe phantsi kweenkqubo eziqhelekileyo kwaye zixhomekeke ekuhlukeni.Iziphumo akufunekanga zisetyenziselwe iinjongo ezithile.Iimveliso ezidwelisiweyo zihambelana ne-ASTM C892. | |||

Bhala umyalezo wakho apha kwaye uwuthumele kuthi