I-Ceramic Fiber Felt / i-RCF Felt

Ingcaciso yeMveliso

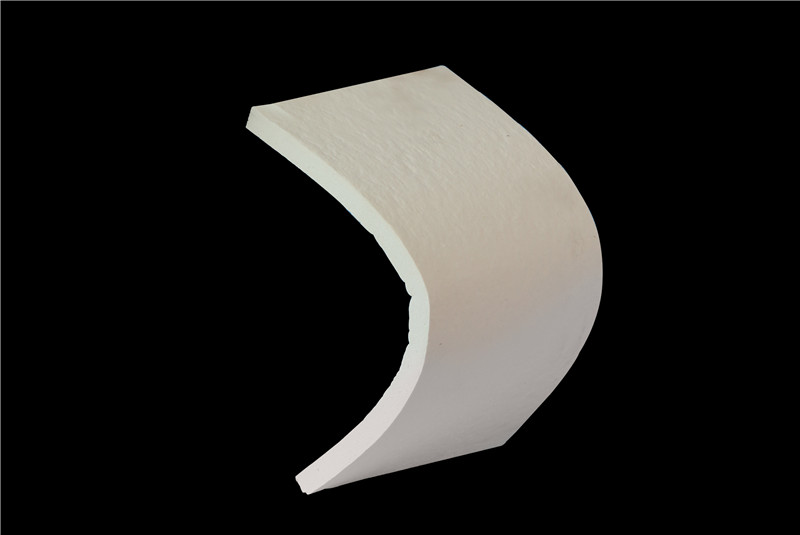

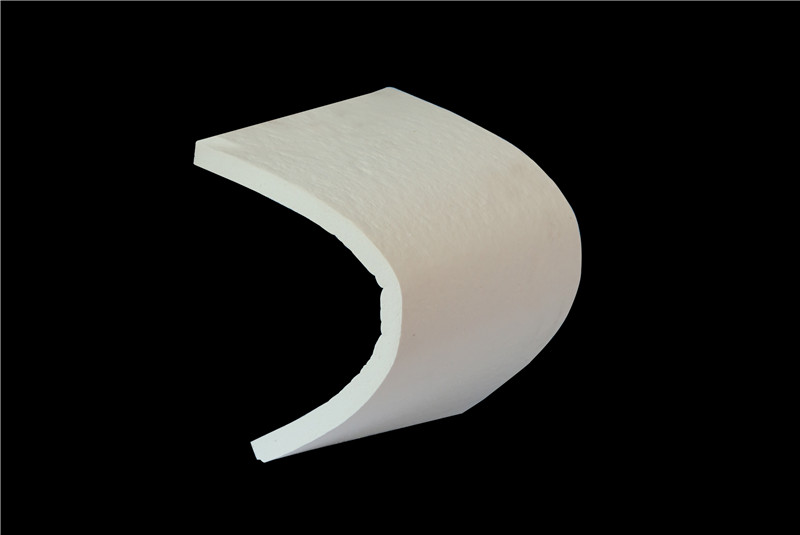

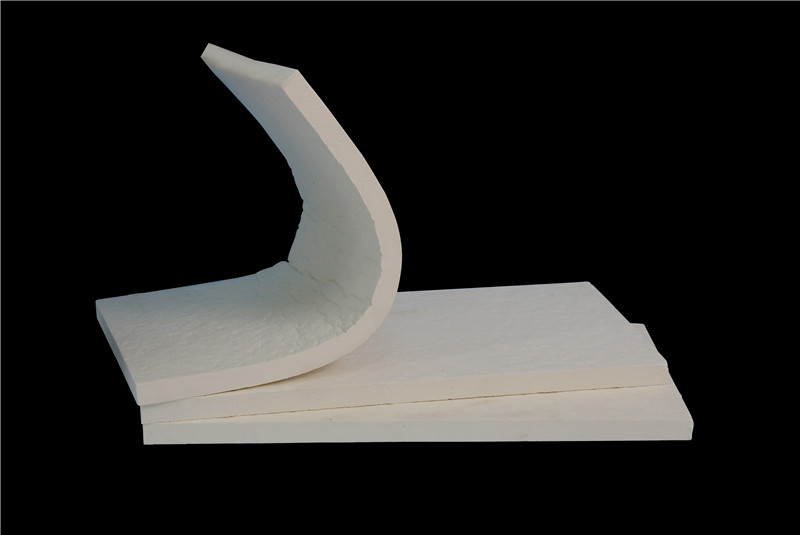

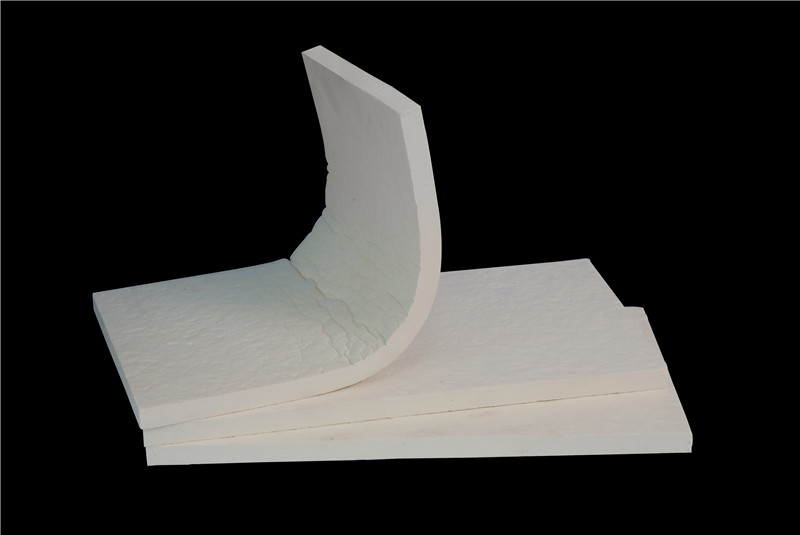

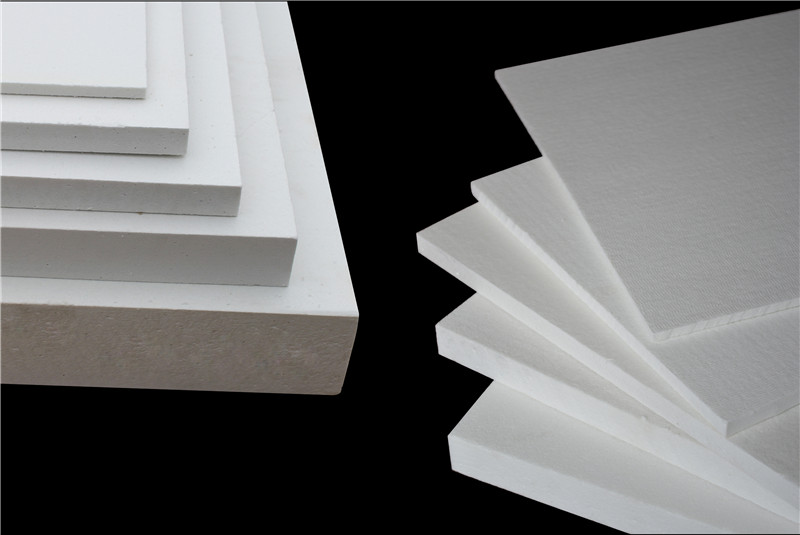

Ifiber yeCeramic ivakale ithatha isambuku sefibre yeceramic njengemathiriyeli ekrwada, ecutshungulwa kwitekhnoloji yokwenza ivacuum, ilula, imathiriyeli ephezulu yokugquma.Ifayibha yeCeramic ivakale inamandla alungileyo kunye nokunwebeka, yimveliso esebenza ngeendlela ezininzi ezisetyenziswa kwiziko elahlukileyo, ibhoyila, i-gasket ephezulu kunye ne-backup linening.

Iimpawu eziqhelekileyo

Umthamo wobushushu obuphantsi, i-Thermal Conductivity ephantsi

Uzinzo olugqwesileyo lweMichiza

Ukuzinza kweThermal okugqwesileyo

Ukufunxwa kweZandi okugqwesileyo

Ithambile kwaye i-Elastic, kulula ukuyisika kunye nokusebenza

Usetyenziso oluqhelekileyo

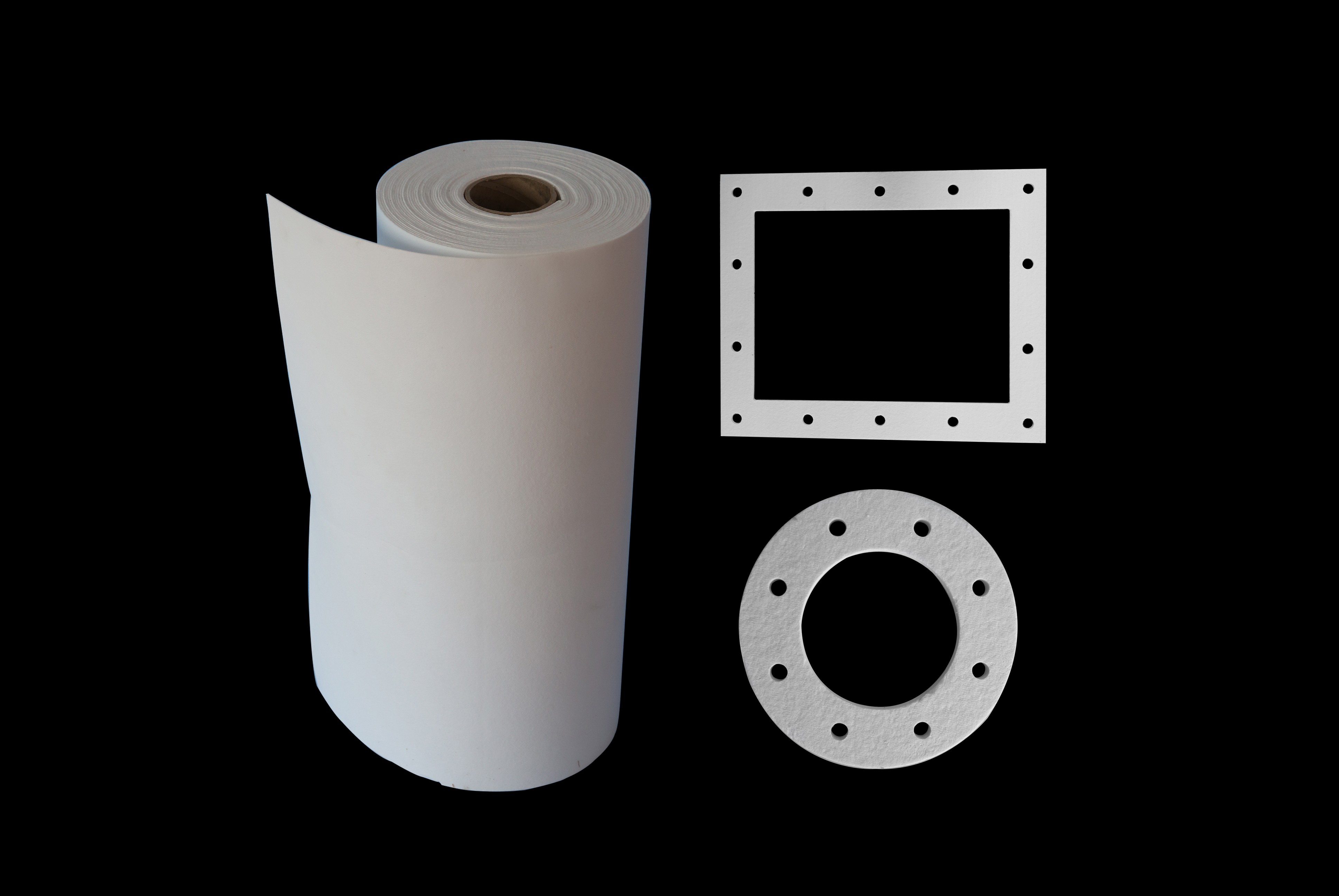

Umgca wesithando somlilo

I-Insulation yezixhobo zokushisa eziphezulu

I-gasket yeqondo eliphezulu, ukutywinwa kokwandisa

I-Insulation yokusabalalisa isinyithi

Iimpawu zemveliso eqhelekileyo

| IFayibha yeCeramic yaziva iiPropati zeMveliso eziqhelekileyo | ||||||

| Imveliso eveziweyo | Kaolin eqhelekileyo | Ubunyulu obuqhelekileyo | Ukucoceka okuphezulu | Ucoceko oluphezulu lwe-Al | I-AZS esezantsi | Umgangatho we-AZS |

| Iqondo lobushushu iBanga℃ | 1050 | 1260 | 1260 | 1300 | 1300 | 1430 |

| Ubushushu bokusebenza obucetyiswayo℃ | ≤950 | ≤1100 | ≤1150 | ≤1200 | ≤1200 | ≤1250 |

| Ikhowudi yeMveliso | I-MYTX-PT-03 | I-MYTX-BZ-03 | I-MYTX-GC-03 | I-MYTX-GL-03 | I-MYTX-DG-03 | I-MYTX-HG-03 |

| Ucutho olusisigxina lomgca (%) | 950℃×24h≤4 | 1000℃×24h≤4 | 1100℃×24h≤4 | 1200℃×24h≤4 | 1250℃×24h≤4 | 1350℃×24h≤4 |

| I-Thermal Conductivity(Mean Temp 500℃)W/(mk) | ≤0.153 | |||||

| Isiqulatho samanzi(%) | ≤1 | |||||

| Ilahleko ekuYilweni(%) | ≤8 | |||||

| Uxinaniso lweNominal(kg/m³) | 180-220 | |||||

| Al2 O3 | 34~36 | 36-38 | 39-42 | 45-47 | 38-40 | |

| Al2 O3 +SiO2 | ≥95 | ≥96 | ≥98 | ≥99 | ≥90 | |

| Al2 O3 +SiO2 +ZrO2 | ≥99 | |||||

| ZrO2 | 5~7 | ≥15 | ||||

| Fe2 O3 | <1.0 | <0.5 | ||||

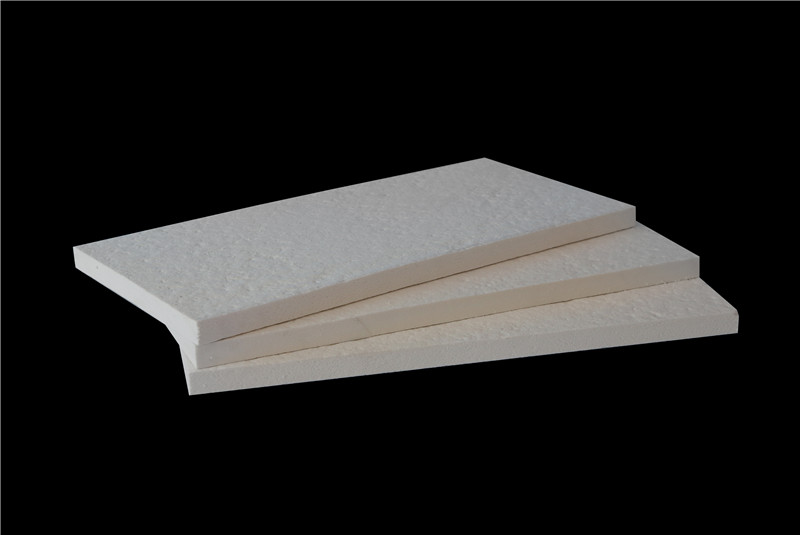

| Ukufumaneka (iMveliso eqhelekileyo) | 600x400x20~50 900x600x10~50 1000x600x10~50 | |||||

| Qaphela: Idatha yovavanyo ebonisiweyo ziziphumo eziqhelekileyo zovavanyo oluqhutywe phantsi kweenkqubo eziqhelekileyo kwaye zixhomekeke ekuhlukeni.Iziphumo akufunekanga zisetyenziselwe iinjongo ezithile.Iimveliso ezidwelisiweyo zihambelana ne-ASTM C892. | ||||||

Bhala umyalezo wakho apha kwaye uwuthumele kuthi